Computerized diagnostics repair revolutionizes vehicle maintenance by offering precise, real-time data analysis. Advanced scanning tools eliminate guesswork, providing faster and more accurate diagnoses for various repairs. This method surpasses traditional manual inspections, enhancing accuracy and efficiency, especially in complex scenarios like bodywork and frame straightening.

In today’s digital age, Computerized Diagnostics Repair (CDR) is transforming the automotive service industry. This modern approach contrasts sharply with traditional methods, offering enhanced accuracy and efficiency. This article delves into the evolution of repair techniques, highlighting the advantages of CDR, such as faster troubleshooting and precise identification of issues. We also explore challenges like initial costs and training requirements. By understanding these aspects, mechanics and car owners alike can appreciate the impact of computerized diagnostics in shaping the future of vehicle maintenance.

- Traditional vs. Computerized Repair Methods: An Overview

- Advantages of Computerized Diagnostics in Repair

- Challenges and Limitations of Traditional Techniques

Traditional vs. Computerized Repair Methods: An Overview

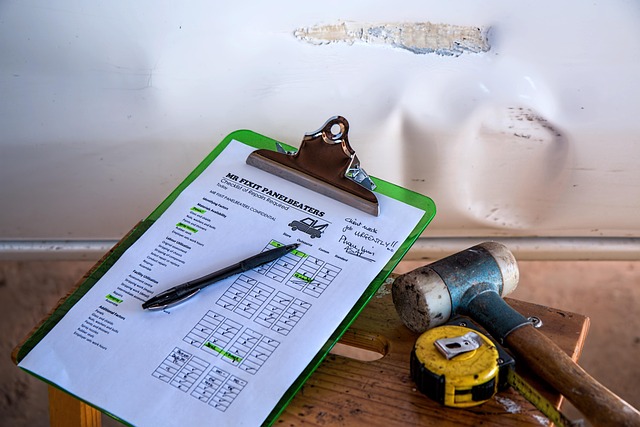

In the realm of vehicle repair, the approach to diagnosing and fixing issues has evolved significantly with the advent of computerized diagnostics. Traditional methods relied heavily on manual inspections, experience, and trial-and-error techniques. Mechanics would often start by examining visible damage, checking fluid levels, and listening for unusual noises to pinpoint problems. This process could be time-consuming and sometimes led to misdiagnosis, especially when dealing with complex modern vehicles.

Computerized diagnostics repair, on the other hand, leverages advanced technology to streamline the entire repair process. Modern vehicles are equipped with onboard diagnostic systems that provide a wealth of real-time data, allowing technicians to connect their tools to the car’s computer network. This enables precise identification of faulty components or systems through code readings and data analysis. Unlike manual methods, computerized diagnostics can accurately detect even subtle issues related to sensors, electronic controls, and engine management systems, making it an efficient and reliable choice for both minor and major repairs, including specialized services like car bodywork services and frame straightening in an automotive body shop.

Advantages of Computerized Diagnostics in Repair

Computerized diagnostics have revolutionized the landscape of vehicle repair, offering numerous advantages over traditional methods. One of the key benefits is precision and efficiency. With advanced scanning tools, technicians can quickly identify issues within a vehicle’s computer systems, engine, and various components. This digital approach eliminates much of the guesswork involved in manual inspections, leading to faster and more accurate repairs.

Moreover, these diagnostics provide detailed data logs, allowing for comprehensive analysis and informed decision-making. This is particularly valuable in complex cases, such as those involving modern vehicles with sophisticated onboard computers and sensors. Computerized systems also facilitate remote troubleshooting, enabling auto body shops and car repair shops to offer faster response times and more convenient services, especially for common issues that don’t require physical on-site visits.

Challenges and Limitations of Traditional Techniques

Traditional diagnostic methods for vehicle repairs often involve a combination of manual inspections, guesswork, and experience. Mechanics rely on their expertise to identify issues, which can be subjective and time-consuming. This approach may lead to several challenges and limitations. For instance, human error is inherent; a mechanic might miss subtle signs or misinterpret symptoms, resulting in incorrect diagnoses or delayed repairs. Additionally, traditional techniques often require more time, increasing the wait times for car owners and potentially impacting their daily schedules.

These methods are particularly challenging when dealing with complex car damage repair or automotive collision scenarios. In such cases, determining the exact extent of the damage and choosing the right repair strategy can be daunting tasks. Traditional practices may not offer precise solutions, leading to suboptimal outcomes or additional costs for clients seeking high-quality car repair services. Computerized diagnostics repair emerges as a game-changer, aiming to streamline these processes and provide more accurate assessments.

Computerized diagnostics repair offers a significant leap forward in efficiency and precision compared to traditional methods. By leveraging advanced technology, technicians can swiftly identify issues, reduce repair times, and enhance overall customer satisfaction. While challenges remain, such as initial implementation costs and the need for specialized training, the benefits of computerized diagnostics repair are undeniable. Embracing this innovative approach ensures that automotive service centers stay competitive and meet the evolving demands of modern vehicle owners.